Apr 28, 2020

Theoretical productivity: 50 m3/h

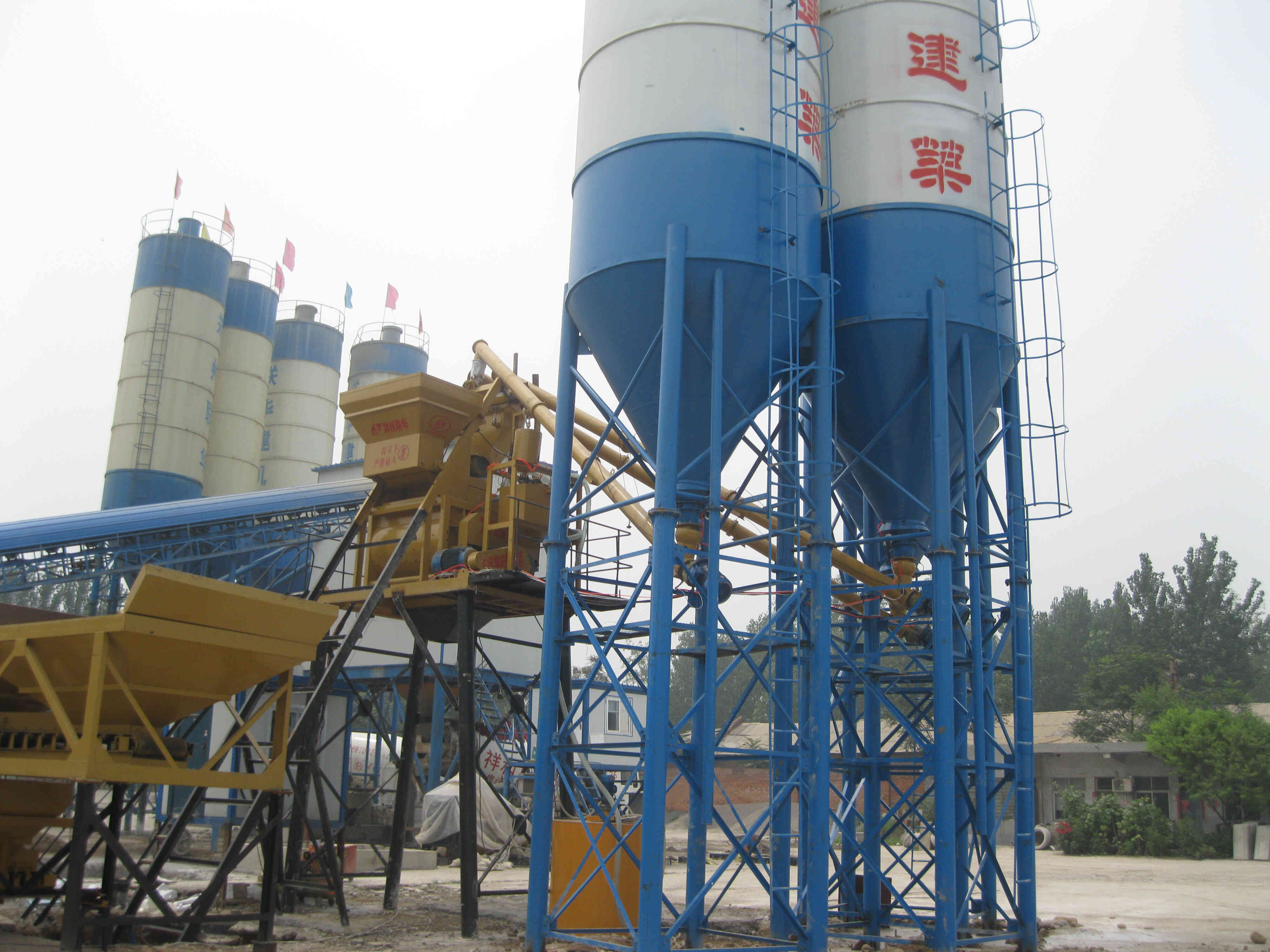

Theoretical productivity: 50 m3/hMixing Machine: JS1000 forced mixer

Batching Machine: PLD1600

Screw Conveyor: LSY219

HZS50 concrete mixing plant is composed of feeding system, measuring (weighing) system, mixing system, electrical system and auxiliary equipments (such as air compressor, water pump etc.), featured by high-precision computer control. And also there are manual control system, automatic head-drop compensation and aggregate moisture compensation. It can be used for industry, construction, road, railway, bridge, water conservation, ports, and so on. Working as the concrete mixing equipment, it can meet the requirements for different forms and specifications.

Features:

Newly-designed: one batching machine supplies materials for two mixers simultaneously

Low investment

Land-saving

Equipments involved are fewer

High-efficiency concrete with high quality is obtained on the premise of accurate measurement of the batching machine.

The cycle operation of batching machine and mixing machine is ideal for bridge construction, large and middle concrete plants.

Parameters:

| Model | HZS35 | HZS50 | HZS60 | ||

| The Whole Station | Max. Productivity | 35 m3/h | 50 m3/h | 60 m3/h | |

| Discharge Height | 1.5-3.8 m | 1.5-3.8 m | 3.8 m | ||

| Working Cycle | 72 s | 72 s | 60 s | ||

| Dimension (LxWxH) | 12922x13000x17245 mm | 15922x13500x17750 mm | 28445x10595x18707 mm | ||

| Power | 75 kw | 90 kw | 105 kw | ||

| Concrete Mixer | JS750 | JS1000 | JS1000 | ||

| Batching Machine | PLD1200 | PLD1600 | PLD1600 | ||

| Pneumatic system | Air Compressor Model | 1.0-7 | 1.5-7 | 1.5-7 | |

| Nominal Displacement | 1.67 m3/min | 1.67 m3/min | 1.67 m3/min | ||

| Rated Discharge Pressure | 0.8 mpa | 0.8 mpa | 0.8 mpa | ||

| Motor power | 5.5 kw | 7.5 kw | 7.5 kw | ||

| Measurement Accuracy of Weighing system | Aggregate | ±2% | ±2% | ±2% | |

| Cement | ±1% | ±1% | ±1% | ||

| Water | ±1% | ±1% | ±1% | ||

| Admixture | ±1% | ±1% | ±1% | ||